Custom Bag Guidelines

For all those times when a stock plastic bag doesn’t quite fit perfectly, look to DigitalPolyBags.com for the custom solution.

With over 30 years of bag making experience, DigitalPolyBags.com understands what will work and, more importantly, what won’t.We look at all the variables when custom designing a bag.

Size, gauge, material, configuration, printing and application all dictate the best solution, and our extensive worldwide network guarantees you and your customer will receive the best value.

While others might be limited in what they can produce, we have virtually unlimited resources to draw from. To grasp an idea of the choices available from DigitalPolyBags.com, examine the options discussed on the following pages.

Poly Bag Dimensions

The first dimension stated when describing a poly bag is the width.

All DigitalPolyBags.com bag measurements are inside diameter (ID).

| Flat Bags | Width X Length plus gauge |

| Side Gusset Bags | Width X Gusset X Length plus gauge |

| Bottom Gusset Bags | Width X Length X Gusset plus gauge |

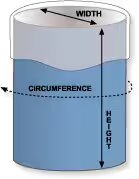

Measuring for Drum Liners

Width = (the circumference of the drum divided by 2) + 2”. It is easiest to use a flexible tape measure and measure around the widest part of the drum.

Length = (height of the drum + the width [diameter]) + 4”. The extra 4” provides the extra material to fold over or tie the bag.

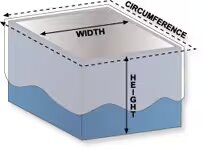

Measuring for Box Liners

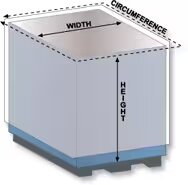

Measuring for Pallet Covers

Types of Materials and Additives

Low Density

- Virgin low density polyethylene complies with FDA and USDA requirements for use with food

- Fractional Melt improves strength in cold temperatures.

Linear Low Density Polyethylene

- Stronger than low density polyethylene and puncture resistant.

- Complies with FDA and USDA requirements for use with food.

High Density Polyethylene

- For use in retail and industrial applications.

Polypropylene

- Preserves freshness with vapor and moisture barriers. Excellent clarity for product presentation.

Static Shielding

- Buried metal construction provides Faraday Cage protection.

Additives

- High Clarity: Adds clarity to the material.

- Metallocene: Adds strength and flexibility. High thermal stability.

- EVA: Adds strength and improves seal ability. For use in cold temperatures to prevent breakage of the bag.

- Low Slip: Reduces slippage when bags are stacked. Used in mattress bags, etc.

- Anti-Static: Protects static sensitive products. Amine-free or regular.

- Ultraviolet Inhibitor (UVI): Prolongs the life of the bag when exposed to sunlight. Used in pallet covers, tarps, etc.

Manufacturing Information / Definitions

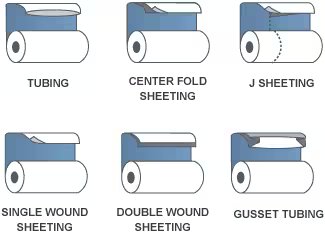

Style of Film

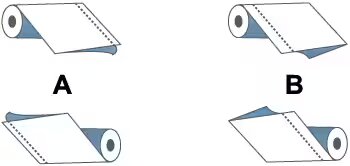

Wind

Styles of Bags - Plain or Printed

- Newspaper Bags

- Draw Tape Bags

- Drawstring Bags

- Fold Over Die Cut Handle Bags

- Flush Cut Die Cut Handle Bags

- Rigid Snap Handle Bags

- M Fold Bags

- Center Fold Bags

- Slide-Seal Bags

- Square Bottom Bags

- Anti-Static Bags

- Header Bags with Die Cut Hang Hole

- Kwik-Fill Bags (for automatic bagging machines)

- Micro Perforated Bags

- Bags with Hang Holes, OSHA holes or vented

- Static Shielding Bags

- Black Conductive Bags

- Lip Bags – Loose, Staple Pack or Wicket

- Side Seal Bags

- Watertight/Leak Proof

- Bags

- Seal Top Bags, Loose

- or Saddle Pack

- Bags on Perforated Rolls

- Pallet Covers/Bin Liners

- Mattress Bags

- T-Shirt Bags

- Merchandise Bags

- Silverware Bags

- Tinted or Opaque Bags

Bottom Seal

BOTTOM SEAL: These bags are cut individually from seamless tubing and are sealed at the bottom of both flat and gusset bags. This is the strongest seal available and is suggested for bags with heavy-duty uses.

Wicket Bag

WICKET BAG: These are side-welded bags with two holes in the lip fixed to a metal wicket. They are used with automatic and semi-automatic bag openers or in manual operations.

Side Seal

SIDE SEAL (SIDE WELD): These bags are made from folded polyethylene sheeting, sealed on each side. This seal (or weld) can be used on flat and gusset bags and is suggested for retail uses.

Reclosable Bags

RECLOSABLE BAGS: Seal Top reclosable bags can be made with or without a tamper evident seal. The use of these bags is preferred when there is the need for multiple entries or repackaging of the bag.

Bags on Perforated Rolls

BAGS ON PERFORATED ROLLS: These bags are made on a continuous roll of seamless tubing perforated at specified intervals for ease in tearing the bag off the roll. The “top” opening can be above or below the perforation.This storage configuration takes minimum storage space and is routinely used for bin liners, pallet covers and very long bags. DigitalPolyBags.com Kwik-Fill preopened bags are suitable for automated bag-filling machines.

Header Bags

HEADER BAGS: These are side-welded bags with a perforated top lip stapled to a header card. They are used with semi-automatic bag opening machinery or in manual operations. They are packed with 100 bags per header card.

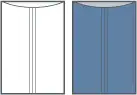

Back Seal

BACK SEAL: For these bags, polyethylene sheeting is folded and sealed along the backside of the bag to form a tube. The bags are cut and bottomsealed and are the required type of bag for wrap-around printing.

Flip-Top Bag

FLIP-TOP BAG: These are side-welded bags with a fold over lip.

Header Pack

Pocket Bag

POCKET BAG: These bags are sealed in separate pockets along their length for the purpose of multiple unit packaging within a single bag.

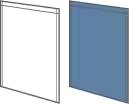

Flat Sheeting

FLAT SHEETING: Sheeting is used for wrapping, lining and dividing layers.

Door Knob Bag

DOOR KNOB BAG: These are side-welded, staple packed bags with a perforated lip and hole just below the top of the bag.